GAS WELDING:

A Special Skill for Special Jobs

Gas Welding is alive and well!

* If you want to create artistic projects, many people will choose this process exclusively.

* At some point, most arc welders will want to, or NEED to use gas welding. I'll help you get started. Then you'll need LOTS of practice!

Seriously, practice is CRITICAL for running great beads.

* If you're doing artistic stuff, you'll want it to LOOK great.

* Eye-hand coordination gets tougher because you're doing more multi-tasking.

This stuff is HAZARDOUS:

* The tuned gas flame can exceed 6,000 F.

* Un-protected eyes can be fatigued & permanently harmed in a short time.

* The acetylene tank could explode under certain conditions: dropping, in a fire, an arc or torch flame penetrating the casing, etc.

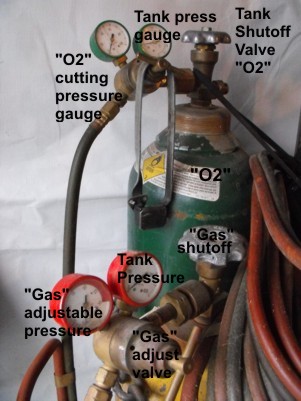

* The oxygen tank starts with 2000 PSI & can literally go like a rocket if the top valve assembly breaks off. (NOTE: stand to the side while opening the 02 tank valve).

* Hitting something already burning with the high pressure torch valve can really accelerate the fire.

So, be careful!

RELATED EQUIPMENT:

These tools are really important:

* Goggles to protect those "baby blues"...

* Tip cleaners to keep the gases flowing...

* Wire brush & other tools to keep things clean.

Photo by: "bobster855 at flickr.com"

Note that both pictures above show that both the torch tip & the filler rod are at about a 45 degree angle.

*Too steep can make the penetration too deep & not pre-heat / too shallow can cause too little penetration.

Let's do it:

* Starting out, it can give you good practice to just put the flame on metal without a filler rod. This helps you get used to the process without worrying about the filler rod too.

* Heat the metal till there's a puddle, then begin moving the flame to create a bead.

* Get the blue part of the flame nearly touching the metal.

* Move in a circular or semi-circular fashion to make it into a bead.

* Aim the flame in the direction you're trying to make the bead. (forehand welding).

* Don't get ahead of the bead or it can make it not hot enough at the puddle.

* Do this for a few times before using a filler rod.

Introduce a filler rod: (usually the same diameter as the pieces that are being welded).

* start the same way as above and keep the rod at a 45 degree angle also. (see the above pics).

* Dip the rod in the puddle frequently, but try not to heat the rod with the flame. (heat the puddle, not the rod).

* Practice running straight beads then work up to following curved paths. (some schools have you write your name with a gas welding bead).

THEN PRACTICE till you can run decent looking beads.

Note that you should be tacking pieces together at least at both ends of where you're welding, to prevent moving of the gap.

Want MORE INFO? Get it from my ebook, "The Arc And Beyond"!