Cutting Torch Work is Super Useful & Fun!

Please read my "Welding Safety Details" page for cutting torch safety via the Welding Safety button at left, or by way of this link:

Watching a fellow worker cut through a railroad railing with a torch really got me hooked on the cutting torch & arc welding. I still have that chunk of rail & use it as an anvil from time to time.

Check out my Cutting Torch video on YOUTUBE:

Click HERE for my Cutting Torch video on YouTube!The first thing I want to do is show you the type of equipment you need to use for your safety, & to help you to do a good job.

Keep the connections real snug but not over-tight. Clean up the thing once in awhile, that includes ME.

Now that you've read my web-pages about safety, & have gathered & donned some gear, let's go:

Lighting the torch & setting the flame:

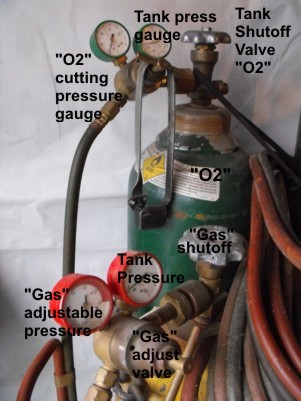

1) Turn on the "gas" tank valve about 1/2 turn (believe me that's plenty)(set the gas at 10-12 PSI).

2) Open the O2 (oxygen) tank valve nearly full open.(set the O2 pressure to about 40 PSI, via the twist knob at the O2 gauges).

3) Open the O2 valve at the green hose.( High pressure valve & mixer valve off).

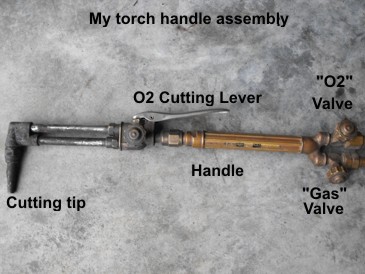

4) With your striker (lighter) in one hand, crack open the acetylene valve on the cutting torch handle & light it. (red hose)

5) Open the acetylene more till the flame separates from the tip, then back it off till it "re-attaches". (that's the max you can get from the tip you're using).

6) Now open the O2 on the torch handle till the blue flames are short & bright.

7) Then push on the high pressure (the long valve, "cutting O2") valve on the handle & re-adjust the O2 valve on the handle till the blue flames are clear & bright.

8)You're THERE!

Check to see that all the holes in the tip end are allowing full flow. If not, shut it off & clean the tips.

To shut the torch off, close the "gas" valve on the torch handle, then the O2 valve.

Then I usually crack the high pressure valve (on the handle) to blow out any gas left.

Now you can have full use of your torch, & see "what it can do". You can cut MANY sizes & shapes of material:

Photo by: "robotskirts at flickr.com"

Photo by: "Elektracute at flickr.com"

Remember that when you're cutting with a torch, there can be a fantastic amount of sparks going everywhere!!

Please be careful & watch out for the other guy as well as yourself!

Want MORE INFO about the torch? Get it from my ebook, "The Arc And Beyond"!