Arc Welding Layout

"Arc Welding Layout" is the final preparation before that

first weld.

Layout to me means: "putting all your cards on the table."

First, I feel that us welders are "Special Mechanics!"

Everything we do is mechanical. So let's talk briefly about auto-mechanics:

* I've re-built 2 engines for myself with the help of good friends.

What do YOU think of first when you totally disassemble an engine?? Probably something like, " how will I remember how this all goes together?"

Here's one example of what happens when things were NOT laid out in order:

A good friend removed my water pump for me before I got home. Then he left for work. That pump had 13 bolts, half of which were different lengths & diameters. I spent a lot of time trying to get them all in the right place!

If he had just laid them out at each related hole, it would have

been MUCH easier. But at least we had the rest of the engine

organized!

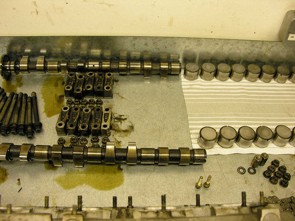

Photo by: "estoril at flickr.com"

Now THAT'S a nice layout! Related items are together & organized for easier assembly.

In later pages about "Welding Projects", I will illustrate other examples of layout ideas.

To Summarize:

Arc Welding Layout includes: verifying that you have all the pieces that you need for the job, organizing them into a logical pattern, & visualizing how you're going to accomplish the whole thing.

Note that there are also other types of layout jobs in the

preparations made before you have all the items cut & ready to

weld. If you're doing pipe-fitting you may need to "layout"

patterns on the pipe to make cuts for various angles needed.

"Layout" could also be considered as being part of your drawing

process, referring to the "layout" of the project.

Finally, let me again emphasize that the purpose in my website is to help you as a BEGINNING WELDER and not to overwhelm anyone!

Go to "Welding Assembly Order" Page

Return to Arc Welding Order main page HOME

Want MORE INFO about "Layout"? Get it from my ebook, "The Arc And Beyond"!

Click HERE to see info about my ebook